I

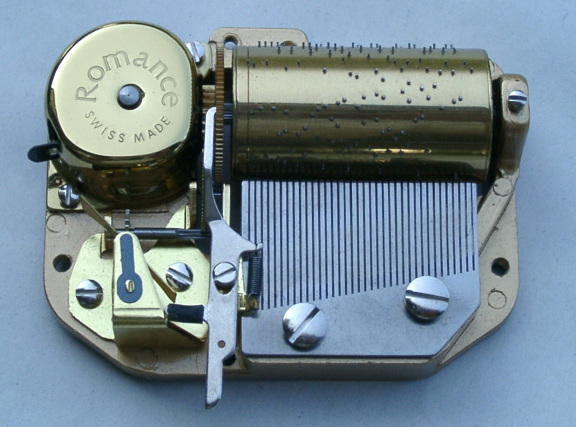

would like to tell you about smaller movements.

You get them with 1

to 4 tunes per cylinder and 12 to 72 teeth per comb.

It consist out

of a cylinder, a comb, a speed controller, a lever to switch it

on and

off and a spring in a capsule to let it run. If there are 2 or

more tunes on a cylinder

a tunechanger is needed. It will shift

the cylinder a millimeter aside after each rotation;

then other pins

are activ. If all tunes are played the cylinder will jump back to the

beginning.

- Cylinder - a tube with small embedded pins.

-

Comb - steel plate with a

series of tuned teeth

which plucked by the pins of the

cylinder;

short teeth ===> high note;

long teeth

===> low note.

To

get a note lower - a small lead weight is attached

underneath a tooth.

A small plastic strip underneath the tip of a

tooth is the damper.

After a tooth has been plucked it will vibrate

for a while. If the next

pin comes into contact with a tooth which is

still vibrating, a raspy

or buzzing sound will be the outcome. If

there is a damper the next

pin will contact at first the damper; the vibration will stop and after

that the tooth will be plucked.

-

Spring - in

a capsule. Smaller movements mainly get wind up with a key

under the

bottom of a box. Via rack-wheels the power of the

spring will let rotate the cylinder.

-

Speed Controller - an upright

shaft; in the upper part a crosswise standing stripe of metal.

Via

rack-wheels there is a connection to the cylinder. The spring will

let rotate the

shaft and the stripe of metal is twirl the air. A

constant rotating speed is adjusted.